As companies scale teams and operations, a purchase order management system becomes a must-have investment. Without a clear understanding of the important use cases expected off the software however, many of these PO system purchases become failed implementations.

What fast scale companies and teams need is an agile system that can do away with manual entry, automate tasks and save costs of additional hires. Systems that can support the following use cases and workflows check the box as winners:

1. No more manual entries and edits

Based on feedback from over 200 companies, before investing in a PO management system, supply chain analysts and managers spend about 40% of their time on manual entries and rework. This can include time spent on receiving purchase orders from customers, keying this information into internal systems or excel sheets, making edits as required before passing to factories and suppliers, and manually reconciling these purchase orders for split shipments. This problem of manual entry is always multiplied because purchase orders from customers to factories are not one-to-one matches. A purchase order from a customer typically has multiple items each needing to go to different factories, and this could be further split across raw material suppliers and manufacturing facilities. Even smaller companies could have hundreds and thousands of purchase orders a day, so the problem of manual entries can add up quickly in costs. The most important and basic functionality to look for in PO management software is the ability to have POs flow in automatically from customers’ systems, with rules built in for edits as required to pass to vendors, and an auto push ability to all vendors required to fulfill the PO.

2. Product data linked to the purchase order

When purchase orders are created and sent to factories, product data is typically detailed out so factories and vendors can fulfill quantities for the right product SKUs. Even with a system for creating, tracking, and pushing POs, style data would have to be manually entered if the product details’ data sets are not linked to the purchase orders’ data sets. Choosing purchase order systems with this link established reduces manual entry and minimizes errors with factories producing the incorrect versions of the product.

3. Easy collaboration with factories and vendors

Purchase order systems are most effective when built for easy participation from and with factories and vendors. There are many questions a company may need clarification on before issuing a PO including questions on available capacity, timing of orders, change in costs, available colors etc. Exchanging message and files with the vendors during the process of issuing purchase orders help minimize delays and errors during manufacturing and delivery. Purchase order systems are incomplete without smart collaboration tools built for vendor use.

4. 3 way data link between retailer/customer order, company costing and margin, and factory PO

Purchase orders flow in many directions, and the sender and receiver information can flip accordingly. As example, a retailer or customer may issue a purchase order to the company for certain products, quantities, costs and expected ship dates. The company will need to take this purchase order and turn it around to a combination of vendors, and in this case the company is the sender, and the vendors are the receivers. Before turning the purchase orders around to vendors however, the digital documents need all details edited – the company’s margins must be deducted to indicate target costs, and quantities, dates and other details must be updated. This is an enormous amount of mathematical calculation to run and to be entered manually without a connected PO management system. Winning purchase order systems connect retailers’ purchase orders with data on internal costing and margins and provide templatized and pre-populated purchase orders to be pushed to factories. A few clicks of a button eliminate the manual overload.

5. Exception management, split shipments, and reconciliation

The next layer of sophistication in PO systems with smart vendor collaboration portals involves exception management. Purchase order delivery is typically plagued with multiple exceptions through the process of manufacturing and shipping. Exceptions could include delayed deliveries, split deliveries, quality issues, cost increases with raw materials and more. Having a friendly user interface that allows easy ability to receive and deal with exceptions becomes critical. A simple but impactful feature here could be the ability to approve or reject each exception. Purchase orders can also be split across multiple deliveries, this may be planned upfront, or the splits may happen as an exception during the process. Tracking each split shipment as its own purchase order and the ability to reconcile delivered items and corresponding invoices and payments are all essential function sets when looking for effective purchase order systems.

6. Visibility during manufacturing and once shipment leaves factory floor

Purchase order management goes beyond creating and managing purchase orders. Visibility into the critical path – including tasks, owners, dates, and progress for every step – is essential to managing orders and reorders. To that end, connecting data sets across product development, vendors, manufacturing, and purchase orders is vital. And on the front end, it requires providing a user interface where the entire supply chain, inbound and outbound, can be visualized through intuitive screens and dashboards.

For more at the intersection of supply chain, platforms, and technology visit www.suuchi.com and www.supplychainsunday.com

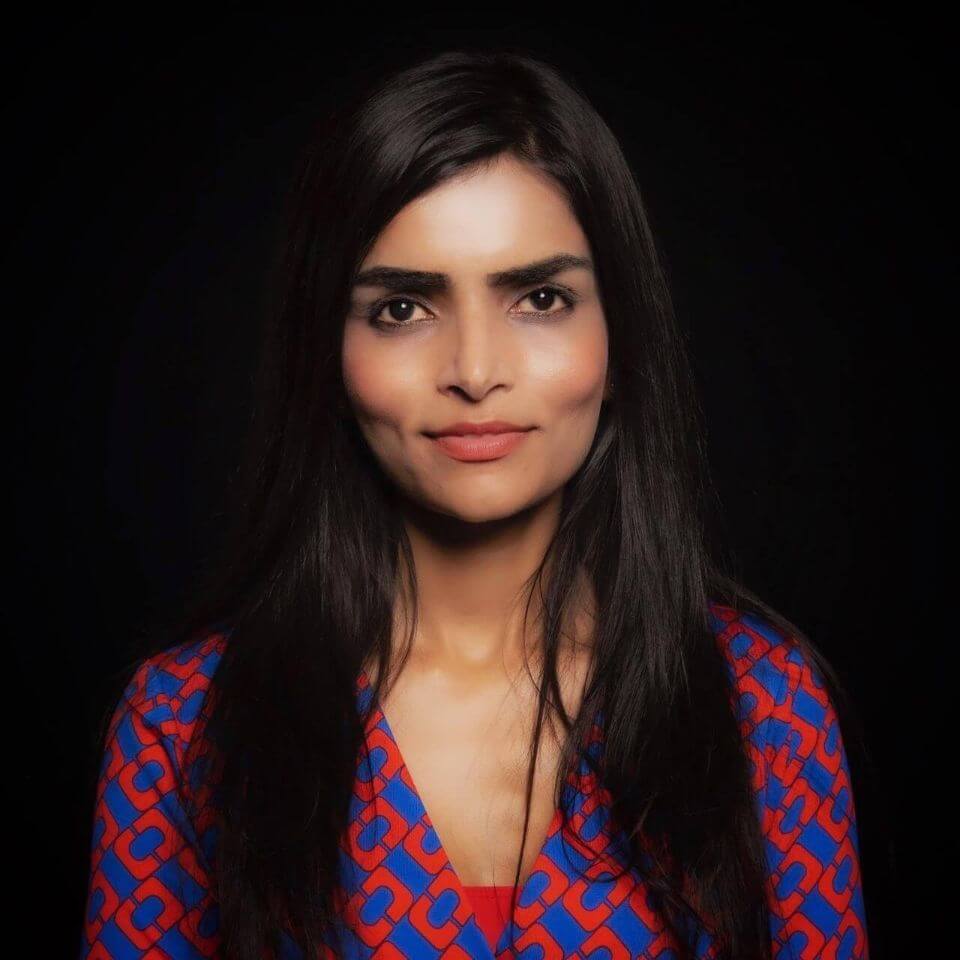

Suuchi Ramesh founded Suuchi Inc. 4 years ago after a 12 year career in technology and predictive data analytics. Before starting Suuchi Inc., Suuchi had scaled the B2B side of multiple tech startups from zero to nearly $30 million. Suuchi now plans to do the same with the GRID. The Suuchi GRID is an intuitive software solution that digitizes the entire supply chain, empowering participation, and providing a single source of truth across suppliers, factories, brands, retailers, warehouses, and customers.