In 1997, world chess champion Garry Kasparov played against IBM’s Deep Blue Supercomputer and lost. When speaking about his experience, he proposed a radical change in perspective: the real challenge is not to determine who is superior- man or machine- but to achieve the right combination: “Human strategic guidance combined with the tactical acuity of a computer [is] overwhelming.”

This insight also applies to supply chain management and operations. People, their experience, and sound judgment are vital for proper decisions. However, understanding how complementary supply chain software can extend human abilities will help achieve maximum profitability and efficiencies. Companies must have the right combination of technology and human brains to result in the most informed decisions and best results. Most importantly, they need to optimize processes based on the interpretation of data and a deep understanding of the trends that inform it.

Now is the time to do an audit on your tech stack and how large of an impact it has on your supply chain operations. Is your supply chain platform driving increased profitability for your business? If planning decisions are made based on data, what data sets are your team using to make these decisions?

When supply chains perform less than optimally, it is usually a sign of poor decision-making. Having the right supply chain software in place will enable superior decision-making in a company’s critical supply chain functions and ensure an efficiently run supply chain. However, understanding what to expect reasonably and what not to expect from supply chain systems is not always clear. At a minimum, supply chain platforms should establish a foundation for operating world-class supply chain processes that enable people to make the best decision for the business.

The Four Pillars of Supply Chain Software

At a minimum, supply chain software needs to provide four foundational impacts. They are:

1. Data Visibility.

Supply chain tools are a view into what is happening in the business: What products do your customers want, the quantities, and the timeframe? What products can suppliers and manufacturing partners produce and with what reliability? What are the real costs for each stage of the product lifecycle: from concept development, sourcing raw materials, production of the finished products, to distributing them to customers? Where are the current and past bottlenecks in the supply chain? How are risks being managed?

When companies have full visibility to the above data points, team members can react and respond effectively in real-time to issues that may arise. Also, having a single source of truth for all decision-makers and internal stakeholders allows for coordinated and consistent responses. Having reliable data reduces the inventory overages that often occur when sourcing and production teams hedge for uncertainty by purchasing excess raw materials and producing extra units, respectively.

2. Data “Slice- and Dice-ability.”

When looking at the data from a granular level, the sheer volume can be overwhelming and not at all useful. Additionally, different supply chain team members accountable for various functions and metrics will need to see the data in different ways. For this reason, supply chain platforms should be able to provide configured views into the data required to make decisions at the level of detail pertinent to the individual decision-maker. For example, production planners may need to see pending customer orders, sales forecasts, and historical sales at a product or customer level to create their production plans effectively. At the same time, managers may want to see historical vendor performance to place said production orders with the factories that will produce those goods at the right price, within the defined timeframe, and at the expected quality.

3. Process Transformation.

The best supply chain platforms automate processes to free up your skilled workforce to focus on high-impact activities. According to a McKinsey report, at least 30% of tasks in approximately 60% of all occupations can be automated. Businesses can feel the positive impact of digitizing end-to-end processes within 3-5 months. It is crucial to identify functions within your supply chain platform that result in quick time to value and the other processes that need digitization to refocus energies to the organization’s most influential and lucrative functions.

Digitizing manual processes and reporting creates greater efficiency and cost savings and the added benefit of creating new repositories of real-time data. This data can be used to optimize supply chain processes, drive innovation, reinforce positive behaviors within your supplier network, and manage issues before they become larger problems and cause delays in execution.

As a leader, it is vital to have accurate data sources to define future strategies and implement process improvements to increase margins and revenues.

4. Alignment with Organization and Process.

There are many different software systems in the market that provide various functionalities. There is a risk of purchasing software that does not align with long-term strategies and overall processes. An effective supply chain tech stack needs to provide solutions for the organization’s process improvement initiatives and support critical decisions that impact profitability. It is important to invest in a system that allows for a single, real-time view of all ongoing processes. Look for a system that emphasizes communication and collaboration and breaks down silos so that critical information is available to all stakeholders.

Speed is crucial- how accessible is all data to make real-time or strategic decisions; how many functions create automation? A configurable system that aligns with current business processes will enable quicker onboarding, less double or triple entry of data, and overall faster decision making.

Next Steps for Your Software Selection Process

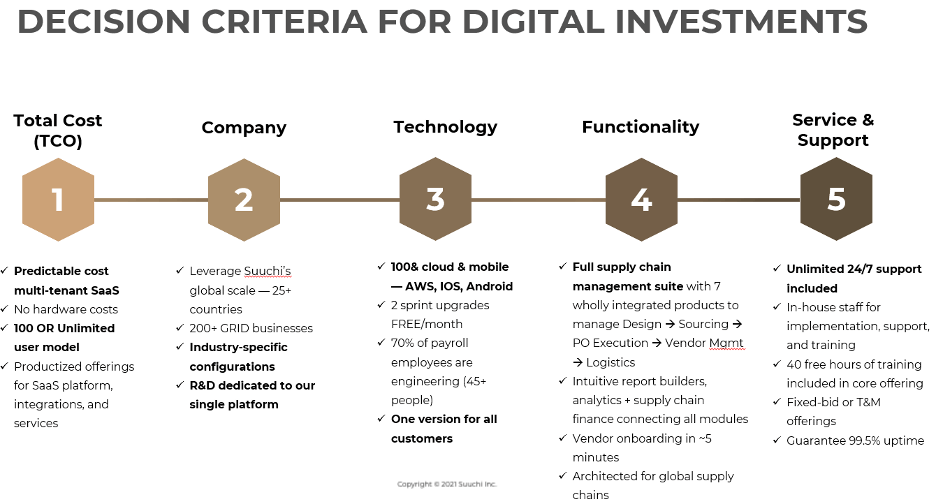

To help you build the right supply chain tech stack, it often makes sense to have a conversation with supply chain software experts such as the team at Suuchi Inc. Getting a fresh perspective can give you insight into your current siloed processes and explore features and functionalities that can help solve them.