In the simplest form, the supply chain is the process of producing finished goods. This process starts with sourcing raw materials, the development stage, making the finished good, and the end-customer receiving those goods. However, that leaves out important supply chain data based on what a customer does with the finished product. Some questions that may arise are:

- What happens after a customer is “done” with this item?

- What happens to the scrap the manufacturer goes through during production?

- What happens to any container the customer does not need when the product is exhausted?

While the answers to these questions may not be simple to get, they are crucial for companies that strive towards a more sustainable supply chain. On any given day, think of all the items you utilize, then think about the container for that item. What happens to the item and the packaging once they fulfill their purpose? You can even apply this exercise to the technology you use every day. What happens when you exhausted it or decide to replace it?

The Impacts of Supply Chain Waste

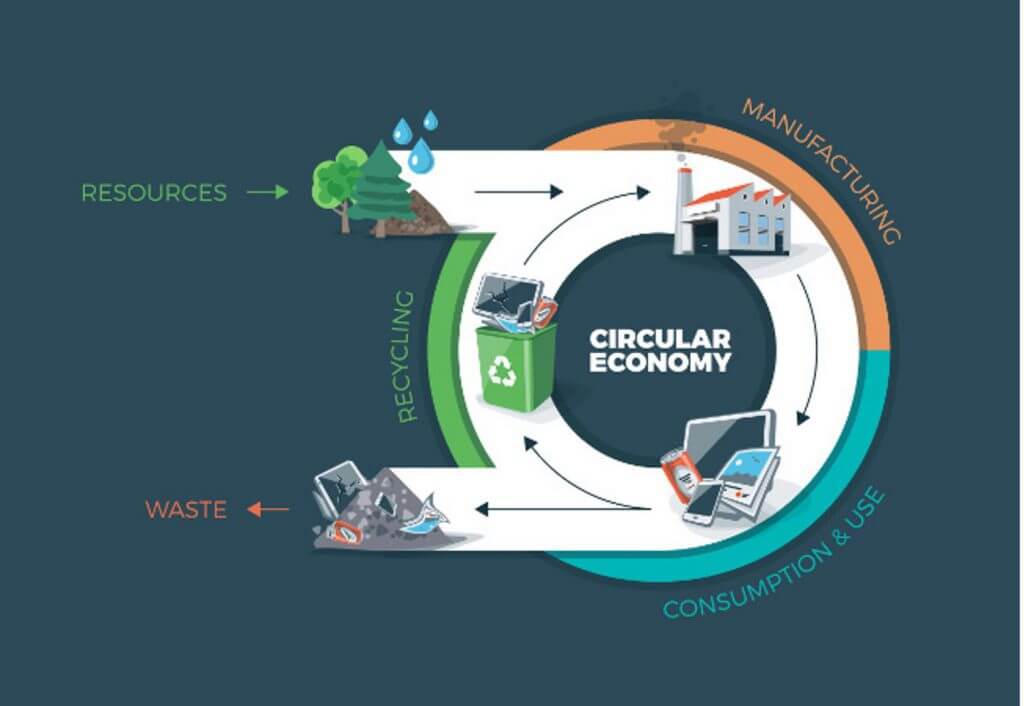

Most of these items would typically make their way to a landfill and be the end journey. The same can be said for the scrap that a company discards during their processes to manufacture an item. Most people did not consider what happened with a product once they were done with it in the past. This is the polar opposite of most consumers today who are much more conscious of their carbon footprints and want to align with companies cognisant of the impacts their production processes and items have on sustainability initiatives. That’s where the circular supply chain comes into play.

What is the Circular Supply Chain?

The circular supply chain’s core concept is that there is no final product life cycle stage. In the circular supply chain, products can be utilized and provide value in a new way. A common example of this is companies that extract precious metals from electronics. Instead of relying on a mining company to obtain the precious metals from the earth, refine them, and create the raw material, a company can now get the recycled metals from electronics and utilize the value that still exists in them.

Examples of Companies with a Circular Supply Chain

Sea Bags utilizes old sailboat sails and turns them into pocketbooks, bags, and backpacks. Otherwise, tossed sails that would find their way to a landfill. However, now they become a sustainable piece of fashion that extends an item’s life that still provides value.

Governments are also working to empower and reward companies that utilize this methodology. They are offering incentives to companies the “greener” they can become.

The Benefits of a Circular Supply Chain

A circular supply chain lends itself to a greener future for society. As companies offer new solutions for used products to find value and not end up in a landfill, they keep the planet cleaner and extend the ROI of their products and materials. It also provides an opportunity for innovative entrepreneurs to disrupt legacy industries that have not yet adopted these practices.

It also means that companies can repurpose the scrap material from the production process to ensure every item has a purpose. Instead of this scrap becoming garbage, it now becomes the raw material for another company to utilize. A circular structure gives the scrap producing company an extra flow of income and reduces the volume of items in a landfill.

How SCM Software Supports a Circular Supply Chain

Supply chain management software can simplify a circular supply chain strategy by digitizing manual tasks across an operations team. When implementing an SCM platform to help support a circular supply chain, businesses should look for a few key features:

- Intuitive UI/UX: An easy-to-use system will allow team members to be up and running quickly with minimal time and money spent on training and maintenance. It also allows for more users to have access and ensure data integrity at every phase of the process.

- Real-time Tracking: Real-time updates enable companies to react quickly to possible difficulties or opportunities to pursue a more beneficial opportunity. As mentioned above, when all participants have access to the relevant updates, businesses can make better choices to support their circular strategies.

- Vendor Management: A large part of any sustainability initiative is working with vendors and suppliers who already have green practices in place. An SCM system with vendor management can empower a company to rate their vendors on key sustainability metrics for smart assignments.

Conclusion

While all businesses cannot transform their supply chains to a more circular approach overnight, the first step is to identify the low-hanging fruit opportunities and what tools will be needed to support them. Next-generation supply chain management platforms, like the Suuchi GRID, can provide the digital backbone necessary for companies to take the first step to a more sustainable future.